BOD INCUBATOR

SUN FOODS EQUIPMENTS BOD Incubators are designed primarily to meet the requirements for tests of Biological Oxygen Demand/Biochemical Oxygen Demand and equipped for controlled incubation and storage of sensitive samples/cultures, microorganism cultures, vaccines etc. These Incubators are designed to meet the testing challenges of the competitive pharmaceutical research field and enhance the scientific efforts of educational institutions and organizations.

- Construction -: Double walled construction. With backside triple.

- Insulation -: 3 inch Thick PUF Insulation ensures stable temperature & reduced energy consumption.

- Observation Door -: Full view observation Acrylic door with gasket to observe sample inside the chamber.

- Heating System -: High quality S.S. Tubular Heaters are used for better heating.

- Air Circulation -: Motorized Blower at back side of the chamber develops unique air flow system which maximum uniform temperature condition inside the chamber.

Unique air flow assures quick recovery after door openings - Blower Motor -: 1/12 HP, TEFC, F-class insulation, Single Phase, 1440 RPM, 230 Volts.

- Safety Features -: 1) Safety standby thermostat to cut of dry heater supply in case of overshoot of temperature 3) Compressor ON delay timer (2min) to safe guard the compressor. 4) In built over load protector provided for hermetically sealed compressor.

- Refrigeration System -: By means of CFC Free hermitically sealed Emerson Copland make compressor with R 134 A for better cooling with ECO friendly refrigerant with time delay to safe guard compressor system.

- Validation Port -: 50 mm validation port hole with silicone rubber seal to insert sensors for validation.

- Lighting -: Interior illumination for working area.

- Supply -: 230 V AC, Single Phase , 50 Hz

- Trays -: Specially designed Stainless steel Rod trays ensure uniform temperature distribution.

- Standard Model -: Inside S.S.304 mirror finish & Outer Mild steel (CRCA) sheet with powder coated.

- Temperature Range -: 5°C to 60°C

- Temperature Accuracy -: ± 0.5° C.

- Temperature Uniformity -: ± 2° C.

- Temperature Control System -: Imported Microprocessor based auto tuned PID controller with CE mark & dual display of set value & process value.

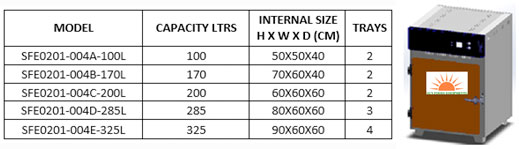

TECHNICAL SPECIFICATION

REQUIREMENT FOR INSTALLATION

- Place the chamber where ventilation is good.

- The chamber must be operated in an ambient of 22◦ C ~ 30◦ C.

- Leave minimum 300 mm. Space from the sides and leave 300 mm. Space from the backside.

- Place the chamber horizontally levelled.

- Give stabilized electric supply (230V ±5%, 50Hz, 1 Phase, 32 Amp). It is recommended to use a voltage stabilizer (KVA).

- Proper grounding of the chamber to get satisfactory operation of chamber.

- Do not test any product in the chamber, which is capable of generating combustible mixtures.