HORIZONTAL DEEP FREEZER (-40°C)

- Construction-: Double walled construction.

- Insulation-: 4 inch Thick PUF Insulation ensures temperature stability with reduced energy consumption.

- Safety Features-: 1) Compressor ON delay timer (2 min) to safe guard the compressor. 2) In built over load protector provided for hermetically sealed compressor.

- Refrigeration System -: By means of CFC Free hermitically sealed Emerson Copland make compressor with R 134 A for better cooling with ECO friendly refrigerant with time delay to safe guard compressor system.

- Supply -: 230 V AC, Single Phase , 50 Hz

- Standard Model -: Inside S.S.304 mirror finish & Outer Mild steel (CRCA) sheet with powder coated.

- GMP Model -: Inside S.S.316 mirror finish & Outer S.S.304 with dull smooth buff finish.

- Temperature Range -: – 40°C

- Temperature Accuracy -: ± 3° C.

- Temperature Control System-: Imported Microprocessor based auto tuned PID controller with CE mark & dual display of set value & process value.

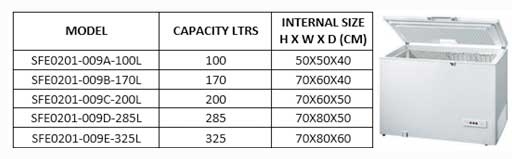

TECHNICAL SPECIFICATION

REQUIREMENT FOR INSTALLATION

- Place the chamber where ventilation is good.

- The chamber must be operated in an ambient of 22◦ C ~ 30◦ C.

- Leave minimum 50 mm. Space from the sides and leave 300 mm. Space from the backside.

- Place the chamber horizontally leveled.

- Give stabilized electric supply (230V ±5%, 50Hz, 1 Phase, 20 Amp). It is recommended to use a voltage stabilizer (KVA).

- Proper grounding of the chamber to get satisfactory operation of chamber.

- Do not test any product in the chamber, which is capable of generating combustible mixtures.

- Stabilized: 230V AC single –phase supply. MCB with proper Earthling.