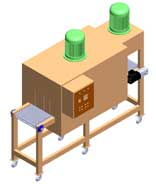

SHRINK OVEN

APPLICATION

Shrink Wrapping of PVC/LDPE films subjecting to temperatures up to 150°C. Pack Size 250mm x150 mm W H

FEATURES

Robust Mild Steel Construction

Variable speed control for AC/PMDC Motor with inverter controller

PID Temperature controller with SSR

Rockwool Insulation for better insulation

Aluminum Pipe Conveyor

Cooling Fan

Aesthetic Control Panel

Bottom to Top Air Control for uniform air motion

TECHNICAL DETAILS

Inside size clear : 300 X 1000 x 200 mm W D H

Outer side size : 800 x 1500 x 1000 mm

Heat Load : 9 KW

Heaters : G I Finned SS conceal Heaters

Temp. : 250C

Drive : ¼ HP DC/AC Geared Motor

Speed : 2.5 to 5 meters/second

Retention Time : 3 Minutes

Blower : 1/2HP

Air Flow : Bottom to Top

Insulation : 100 mm.

Control : Integrated Process Control System for complete Line with Temperature Control Line Speed Control with Phase

Indicator Light Ammeter Main Switch Push Buttons

Conveyor : Aluminum Rods with Chain drive.

Tunnel Window : Teflon with Asbestos Cloth

Voltage : Supply 415 V 3 Phase Neutral

STRUCTURE

Oven Body will be floating Body type. The Body & the Conveyor will be mounted on a Heavy structure of 35 mm M.S. angle. The Body will 1mm thick CRCA Sheet.

The Roller will be Steel Pipe with shaft on both ends. Sprocket mounted on lubricated Bush Bearing on Both end.

The Roller assembly mounted on independent frame structure of suitable size.

CHAIN

Heavy duty Roller Chain Size ½” to drive all rollers with Guide & tensioning arrangement.

DRIVE

¼ HP AC/DC Induction motor with suitable worm Gear Box with chain drive to main Roller Chain.

PAINT

Structure suitable pre-treated, 2 coals of primer & suitable High temp Paint.

INSULATION

Glass wool / Rock wool / Mineral Wool / 100 mm thick.

BLOWER

500 CFM ½ HP. centrifugal Blower top mounted directly driven.

CONTROL PANEL

Side standing electrical cum Instrumentation panel Housing.

Ammeter, Voltmeter, Phase indicator.

Electronic temp Controller.

Motor Starter.

Motor Drive.

With all switchgear.

Neatly wired, lugged & terminated.