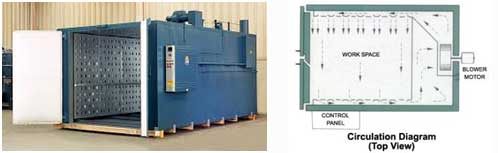

WALK IN OVENS

1) HIGH TEMPERATURE WALK IN OVEN

For annealing, sintering, precipitation hardening, burn off or any other high temperature processing of large or numerous parts. Constructed with an isolated inner oven to eliminate heat transfer and leakage at seams commonly found in standard panel construction. Designed and constructed for long, hard, continuous use with the temperature uniformity required for consistent results at elevated temperatures.

STANDARD FEATURES

- Controls

* Digital, microprocessor based, thermocouple actuated, indicating temperature controller -Modulating burner on gas-fired ovens

* Motor control push buttons, on-off heat switch.

* Easy-to-see pilot lights

- Safety Equipment -Electric Oven

* Adjustable, thermocouple actuated, manual reset excess temperature controller.

* Separate heating element control contactors

* Re circulating blower airflow safety switch.

- Safety Equipment – Gas Oven

*Adjustable, thermocouple actuated, manual rest excess temperature controller.

* Electronic flame safeguard protection

* Powered forced exhauster for combustion venting

* Exhauster air flow safety switch

* Re circulating blower air flow safety switch

* Purge timer

*High gas pressure switch

*Low gas pressure switch

* Latch-type manual reset main gas valve

*Testing device to test tight closure of main gas valve

*Solenoid blocking valve up to 400,000 BTU/HR heat

input; motorized backup valve and vent valve over 400,000 BTU/HR

- Construction

*Choice of air flow patterns

*Adjustable patented opposed louvers on full coverage supply and return ductwork

*exceptionally heavy duty doors

* Explosion venting latches

*Doors equipped with expansion joints on inner face to guarantee uniform sealing at all temperatures.

*Inner and outer doors gaskets; inner gasket seals directly against door plug; outer gaskets seals against front face of oven.

* 3/8 steel plate oven front to guarantee rigid sealing surface at all temperatures.

*Slip flashing at door openings to allow inner oven to expand without effecting outer oven or door sealing surface

* Aluminized steel exterior with enamel finish

* Brushed stainless steel exterior control panel face

Every oven fully assembled and individually factory tested

STANDARD EQUIPMENT

230 volts, 3 – phase, 50 Hz

Other electrical characteristics available

- All Models

Exclusive construction is far superior to commonly used panel construction Consists of an isolated inner oven completely surrounded by insulation to eliminate heat transfer from through metal and hot air leakage at panel seams. Insulated floor standard. Trilite Green enamel painted aluminized steel exterior.

- Electric Models

each features completely wired, side access control panel enclosing terminals for incoming power temperature controllers, push buttons and heating element contactors electrically interlocked to shut off heat for cooling. Incoloy sheathed tubular heating elements on all models. The 6500C models have a heat chamber high limit control.

- Gas Models

1,000 BTU natural gas at 6″ water column pressure 1″ NPT inlet

other gas characteristics available

Control panel as detailed above and safety devices as listed on the front of this bulletin. A 325 CFM powered forced exhauster in included up to 800,000 BTU/HR, at 880,000 BTU/HR a 650 CFM exhauster is included. Both exhausters have 6″ outlets. Automatic preignition purge period and push button electric ignition contributes to ease of operation. Modulating gas burner is protected with electronic flame safety relay.

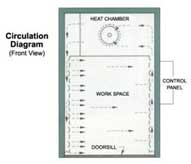

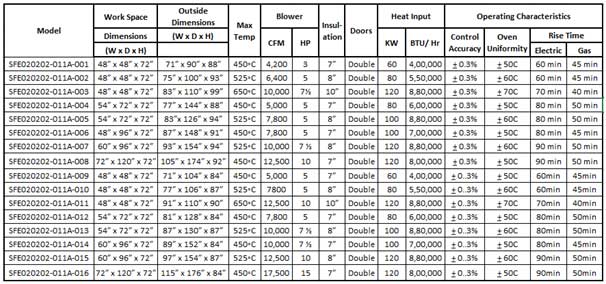

011A-001 TO 011A-008 SERIES

Combination Air Flow

Combination airflow for random shapes and sizes or for large bulky objects where heated air can move upward around and through the load.

011A-008 TO 011A-016 SERIES

Horizontal Air Flow

Horizontal airflow for applications where heated air must move sideways to pass through a load such as trays or flat sheets.

• 450◦C Models

16 gauge aluminized steel interior throughout. 7″ of 675◦C10-lbs. /cf. density industrial rock wool insulation throughout walls, doors and ceiling. 4″ thick insulated floor with 1/8″ steel plate cover

• 525◦C Models

16 gauge aluminized steelwork space interior with 16 gauge 304 stainless steel heat chamber interior. Stainless steel re circulating blower. 8″ of 650◦C 10 lbs. /cf. density industrial rock wool insulation throughout walls, doors and ceiling of work space. Oven heat chamber insulated with 2″ of 19000C block surrounded by 6″ of 650◦C 10 lbs. /cf. density industrial rock wool insulation. 6″ thick insulated floor with ¼” steel plate cover.

• 650◦C Models

16 gauge 304 stainless steel interior throughout. Stainless steel re circulating blower. 10″ of insulation” consisting of 2″ of 1050◦C block, surrounded by 8″ of 650◦C 10 lbs. /cf. density industrial Rockwool insulation throughout walls, doors and ceiling. 7″ thick insulated floor with ¼” stainless steel plate cover.

2) WALK IN HORIZONTAL (AIR FLOW REAR HEAT CHAMBER