MUFFLE FURNACE

MUFFLE FURNACE APPLICATIONS

| Ignition tests | Gravimetric analysis |

| Heat treating steel parts and Gears | Heat treating Gears |

| Coal sampling | Quench testing |

| Organic and inorganic ashing | Research facilities in chemistry |

| Chemical analysis | Annealing loss determination |

| soils & aggregates cement Testing | Development of coatings and ceramics |

| Glass blowing lab | Rice laboratory |

| Plastic tensile strength test | Stoneware samples firing |

Muffle furnace is used for example for drying enamel coats, heating ceramic products, glass working etc.

TYPES OF MUFFLE FURNACE

1) TEMP 930°C

2) TEMP 1200°C (HIGH TEMP)

3) REFRACTORY FURNACE (TEMP. 1200°) HIGH TEMP

4) CRUCIBLE FURNACE (TEMP 1150°C)

5) BENCH FURNACE

6) BOX FURNACE

7) PIT FURNACE

8) BOTTOM LOADING FURNACE

9) TEMPERING FURNACE (ELECTRIC & GAS)

10) 1400°C FURNACE

11) TUBE FURNACE

12) 1700°C FURNACE

1) TEMP. 930°C FURNACE (SFE0301)

2) TEMP 1200°C (HIGH TEMP) (SFE0302)

3) REFRACTORY FURNACE (SFE0303)

- Construction-: Horizontal rectangular muffle.

- Insulation-: Heating element wounded with high grade ceramic wool blanket and the gaps are filled with glass wool to avoid heat loss.

- Door -: Single door made of brick work and cementing fitted in with single

Hole at center. - Heating system-: Heating is affected by means of element made of best

QualityNichrome wire wounded on the muffle. - Safety -: Energy regulator to control heating elements for extra heating and

Safety of equipment. - Supply -:230 V AC, Single Phase , 50 Hz

- Temperature Range -: Maximum working temperature up to 930° C.

- Standard Model -:Inner made of ceramic pot, Outer case made from thick

Gauge Mild Steel (CRCA) sheet. - Control system-: Imported Microprocessor based auto tuned PID controller with CE mark & dual display of set value & process value for precise control of temperature.

|

MODEL |

INTENAL SIZE DXWXH cm |

RATING KW |

TEMP. RANGE |

DRIVE |

|

SFE0301A |

23X10X10 |

1.6 |

UP TO 930◦C |

|

|

SFE0301B |

30X15X15 |

3.3 |

UP TO 930◦C |

|

|

SFE0302A |

23X10X10 |

1.8 |

1150◦C TO 1200◦C |

|

|

SFE0302B |

30X15X15 |

3.5 |

1150◦C TO 1200◦C |

THYRISTER CIRCUIT REDUCES |

|

SFE0302C |

30X20X20 |

4 |

1150◦C TO 1200◦C |

THYRISTER CIRCUIT REDUCES |

|

SFE0302D |

45X22.5X22.5 |

7 |

1150◦C TO 1200◦C |

THYRISTER CIRCUIT REDUCES |

|

SFE0303A |

30X15X15 |

3.5 |

1150◦C TO 1200◦C |

REFRACTORY FURNACE |

4) CRUCIBLE FURNACE ( SFE0304)

- Construction- Circular Construction with heavy gauge CRCA sheet

- Exterior – Made of Heavy gauge CRCA sheet.

- Working Chamber – Made of Grooved Refractory.

- Temperature Range – Maximum working temperature 1150°C Continuous.

- Heating System / Safety / Supply / Standard Model / Control System – Same as per above.

|

MODEL |

INTENAL SIZE DXWXH cm |

RATING KW |

TEMP. RANGE |

|

SFE0304 |

9.5 DIA.X 10 DEEP |

1.4 |

1150◦C CONTINUOUS. |

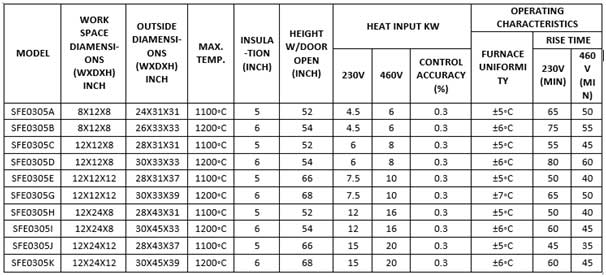

5) BENCH FURNACE ( SFE0305)

SFE standard 11000C and 12000C furnaces provide for a variety of heat treating applications. Precision microprocessor based temperature controls and energy saving insulation maximize the cost efficiency and performance of these rugged units. Five sizes from 0.44 to 2.0 cubic feet. Ideal for general purpose heat treating of tools, dies and other parts.

- CONSTRUCTION

Heavy gauge aluminized steel cabinet with enamel finish

Brushed stainless steel control panel face

Gas spring assisted manually operated vertical lift door

Door hot side faces away from operator at all times

High temperature alloy wire heating elements supported by rugged ceramic plates

Energy saving lightweight ceramic fiber insulation reduces operating costs

Fast heat –up

Heating elements located on sidewall and roof for excellent temperature uniformity throughout workspace

Ceramic hearth tray

SPECIFICATIONS

- CONTROLS

Digital, microprocessor based, thermocouple actuated, indication temperature controller

On- off heat switch

Easy to see pilot light

- SAFETY EQUIPMENT

Adjustable, thermocouple actuated, manual reset excess temperature controller

Separate heating element control contactor

Door interlock switch turns off power to heating elements when door is opened restores power when door is closed

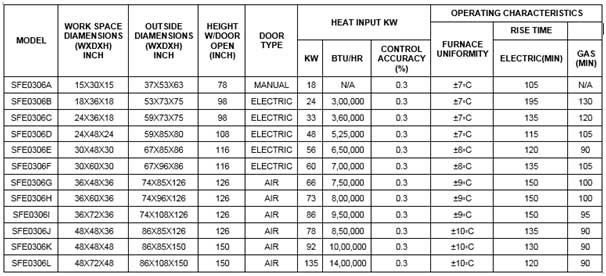

6) BOX FURNACE ( SFE0306)

SFE standard 11000C heat treating furnaces are used for a variety of heat treating applications such as tempering, hardening, sintering or firing, including those requiring inert atmospheres. Precision microprocessor based temperature controls and energy-saving insulation maximize the performance of these rugged units. Twelve standard models from 3.9 to 96 cubic feet, built for long, hard, continuous use.

STANDARD FEATURES

- CONTROLS

Digital, microprocessor based, thermocouple actuated, indicating temperature controller.

Modulating burner on gas furnaces.

Motor control push buttons and on-off heat switch.

Easy-to-see pilot light.

SAFETY EQUIPMENT – ELECTRIC FURNACE

Adjustable, thermocouple actuated, manual reset excess temperature controller.

Separate heating element control contactors.

Door interlock switch turns off power to heating elements when door is opened; restores power when door is closed.

SAFETY EQUIPMENT – GAS FURNACE

Adjustable, thermocouple actuated, manual reset excess temperature controller.

Electronic flame safeguard protection.

Combustion air blower with air flow safety switch

Purge timer.

High gas pressure switch

Low gas pressure switch

Latch-type manual reset main gas valve

Testing device to test tight closure of main gas valve.

Solenoid blocking valve upto 400,000 BTU/HR heat input; motorized backup valve and vent valve over 400,000 BTU /HR

CONSTRUCTION

3/16″ steel plate reinforced furnace shell

1/2″ thick steel front plate

Brushed stainless steel control panel face

Powered vertical lift door

Door hot side faces away from operator at all times.

Energy saving lightweight ceramic fiber insulation reduces operating costs.

Heavy-duty ceramic hearth plates supported by firebrick piers.

Excellent temperature uniformity throughout workspace.

Fast heat up and cool-down

- Every furnace fully assembled and individually factory tested.

SPECIFICATIONS

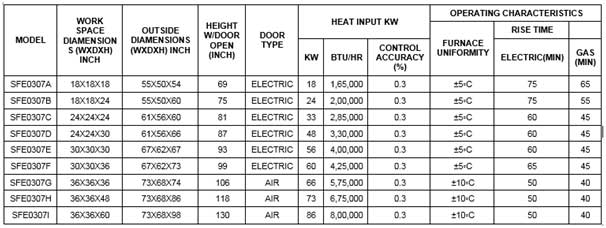

7) PIT FURNACE ( SD03)

SFE standard 11000C pit furnaces are used for a variety of heat treating applications including those requiring inert atmospheres where overhead handling equipment is used. Full opening door exposes entire workspace for easy loading. Precision microprocessor based temperature controls and energy-saving insulation maximize the cost efficiency and performance of these rugged units. Nine standard models from 3 to 45 cubic feet built for long, hard, continuous use.

- Construction

3mm steel plate reinforced furnace shell

4mm thick steel front plate

Powder coated control panel face

Powered vertical lift door

Door hot side faces away from operator at all times.

Heavy duty ceramic hearth plates supported by firebrick piers.

Every furnace fully assembled and individually factory tested.

STANDARD FEATURES

- CONTROLS

Digital, microprocessor based, thermocouple actuated, indicating temperature controller.

Modulating burner on gas furnaces.

Motor control push buttons and on-off heat switch.

Easy-to-see pilot light.

- SAFETY EQUIPMENT – ELECTRIC FURNACE

Adjustable, thermocouple actuated, manual reset excess temperature controller excess temperature controller.

Separate heating element control contactors.

Door interlock switch turns off power to heating elements when door is opened; restores power when door is closed.

- SAFETY EQUIPMENT – GAS FURNACE

Adjustable, thermocouple actuated, manual reset excess temperature controller.

Electronic flame safeguard protection.

Combustion air blower with air flow safety switch.

Purge timer.

High and low gas pressure switches.

Latch-type manual reset main gas valve.

Testing device to test tight closure of main gas valve.

Solenoid blocking valve up to 400,000 BTU/HR heat input; motorized backup valve and vent valve over 400,000 BTU/HR.

SPECIFICATIONS

STANDARD EQUIPMENT

- ALL MODELS

415 volts, 3-phase, 50Hz

Other electrical characteristics available

Wall insulation, 7″ thick, consisting of:

5″ of 12500C, 8 lbs. /cf. ceramic fiber blanket.

2″ of 9250C, 4 lbs. /cf. ceramic fiber blanket.

Roof insulation 8″ thick consisting of:

4″ of 12500C insulating castable.

2″ of 10500C, 18 ½ lbs/cf block insulation.

Furnace shell is made of 3mm thick steel plate reinforced with structural steel plate reinforced with structural steel. Powered door supported at rear by heavy duty shaft and pillow block bearings, Open door exposes entire workspace for easy loading. Floating door construction provides excellent heat seal by pressing soft insulation against 4mm thick steel top plate. Exterior painted with Ivory & Red enamel.

Each features completely wired, side access control panel assembled on the furnace enclosing terminals for incoming power, temperature controllers push buttons and pilot lights.

- ELECTRIC MODELS

Safety devices as listed on the front of this bulletin. Heating element contractors electrically interlocked with door opens and restore power when closed. High temperature alloy wire heating elements supported in Refractory Bricks. Heating elements located at four sidewalls.

- GAS MODELS

1,000 BTU natural gas at 2 psig at 2 psig pressure;

1” NPT inlet up to 800,000 BTU/HR

1 ¼” NPT 850,000 to 1,000,000 BTU/HR

Other gas characteristics available

Safety devices as listed on the front of this bulletin. Automatic preignition purge period and push button electric ignition contributes to ease of operation. Modulating gas burners fire from opposing sides to circulate heated air through the workspace. Gas burners protected with electronic flame safety relay. Door interlock switch drives main burners to low fire when door is opened and restores control when door is closed.

- ELECTRIC DOOR

Door pivots upward above furnace, clearing top opening for easy loading. In the closed position, full door weight seats door firmly against furnace top plate. Structural steel pivot arms supported on furnace top plate by rugged pillow blocks are connected to a heavy-duty electromechanical actuator. The door is controlled by a switch at the furnace control panel.

- AIR DOOR

Door pivots upward above furnace, clearing top opening for easy loading. In the closed position, full door weight seats door firmly against furnace top plate. Structural steel pivot arms supported on furnace top plate by rugged pillow blocks are connected to a large diameter air cylinder. The door is controlled by a manual air valve with supply filter, lubricator and regulator.

8) BOTTOM LOADING FURNACE ( SFE0308)

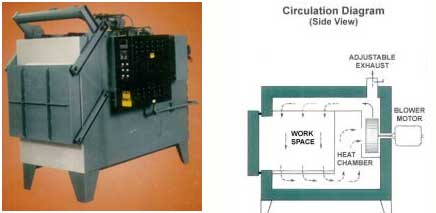

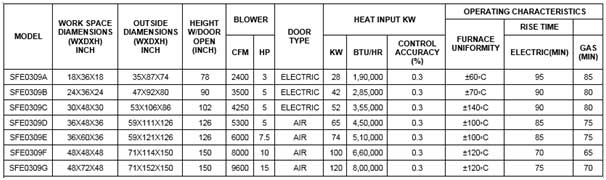

9) TEMPERING FURNACE ( SFE0309) (ELECTRIC & GAS)

750◦C

FORCED CONVECTION

ELECTRIC AND GAS TEMPERING FURNACES

SFE standard 750◦C tempering furnaces are used for a variety of heat-treating applications including those requiring inert atmospheres. Recirculating blower provides high velocity vertical down airflow for excellent heat transfer from 425◦C to 750◦C. Precision microprocessor based temperature controls and energy-saving insulation maximize the performance of these rugged units

CONSTRUCTION

– Vertical down airflow specifically designed for tempering.

– High pressure, air-cooled, stainless steel recirculating blower.

– Adjustable patented opposed louvers on full coverage supply and return ductwork.

– 3/16″ steel plate reinforced furnace shell.

– ½” thick steel front plate

– 16 gauge stainless steel interior.

– Work space bottom reinforced with stainless steel grid

– Brushed stainless steel control panel face.

– Powered vertical lift door; hot side faces away from operator

– Energy – saving light weight ceramic fiber insulation

– Fast heat – up and cool-down.

– Built-in baffles prevent radiant heat

– Adjustable fresh air intake and exhaust dampers

– every furnace fully assembled and individually factory tested

SPECIFICATIONS

STANDARD EQUIPMENT

- All Models

– 230 Volts, 3-phase, 50 Hz

– Other electrical characteristics available Wall insulation, 7″ thick, consisting of

– 1″ of 12500C, 8 lbs. / cf. ceramic fiber blanket

– 2″ of 9250C 4 lbs. / cf. ceramic fiber blanket

– 2″ of 10500C 15 lbs. / cf. block insulation

– 2″ of 6500C, Rockwool insulation

Floor insulation, 6 ½ ” consisting of:

– 4 ½ of 12500C insulating firebrick

– 2″ of 6500 C 18 ½ lbs./cf. block insulation

- ELECTRIC MODELS

Safety devices as listed on the front of this bulletin, heating element contactors electrically interlocked with door to shut off power to beaters as door opens and restore power when closed. High temperature alloy coiled wire-heating element supported in alloy rack, heating elements located in heat chamber upstream of the recalculating blower. Exhaust outlet 4′” diameter. - GAS MODELS

– 1,000 BTU natural gas at 2 psig pressure; 1″ NP inlet up to 800,000 BTU/HR

– Other gas characteristics available.

Safety devices ass listed on the front of this bulletin. Automatic preignition purge period and push button electric ignition contributes to ease of operation. Modulating gas burner fires into chamber upstream of the recalculating blower. Gas burner protected with electronic flame safety relay. Door interlock switch drives main burner to low fire when door is opened and restores control when door is closed. Exhaust outlet 6″ diameter.

Furnace shell is made of 3/16″ thick steel plate reinforced with structural steel. Doorsill constructed from firebrick to protect furnace during loading. Stainless steel grid at bottom of workspace to distribute loading. Soft insulation on door provides an

excellent heat seal by pressing against the vestibule refractory and ½ ” thick steel front plate. Exterior painted with Trilite Green enamel, each features completely wired side access control panel assembled on the furnace enclosing terminals for incoming power, temperature controllers, push buttons and pilot lights.

- ELECTRIC DOOR

Door pivots upward above furnace, clearing front for easy loading. In the closed position, full door weight seats door firmly against furnace face. Structural steel pivot arms are supported at furnace sidewalls by bearings and connected to a heavy-duty electro-mechanical actuator. The door is controlled by a switch at the furnace control panel.

- AIR DOOR

Door rises vertically in front of the furnace hanging from heavy-duty roller chain, sprockets, shaft and pillow block bearings. In the closed position, rollers at the sides of the door engage support brackets to force the full door weight against the furnace face. Large diameter air cylinder rotates support shaft to lift the door. A manual air valve controls the door with supply filter, lubricator and regulator.

OPERATING INSTRUCTION

Switch on the main switch.

Switch on the main switch on furnace control panel.

After switching on main switch ensure that ammeter shows reading & pilot lamp is on.

Set the desire temp in temp controller by controlling fine & coarse adjustment knobs.

Open the door of the furnace.

Put the material inside the furnace.

Close the door of the furnace.

Wait until desire temperature reaches.

Ensure that after reaching the desired temp pilot lamp becomes off.

Allow material to stay inside for desired time period.

After desired time period open the furnace door and remove the material.

If other material is ready put inside or else switch off the main switch in control panel

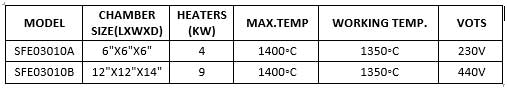

10) 14000C FURNACE

DESCRIPTION

- Specially designed to site the requirement of various fields like education, metallurgical, Magnets, and Material testing laboratory.

- Housing made of heavy gauge M.S. duly finished in epoxy powder coated shade.

- High-grade silica boards and layers of ceramic insulation provided to minimize the heat loss.

- Silicon carbide heating element provided in refractory type heating chamber for superb temperature Uniformity.

- The temperature is being controlled by Microprocessor based auto tuning temperature controller having digital indicator.

- The control panel consists main temp. Controller (SCR power controller) MCB, HRC fuse etc., and mounted at one side of the unit.

- Optional programmable controller with thyristor for soft start.

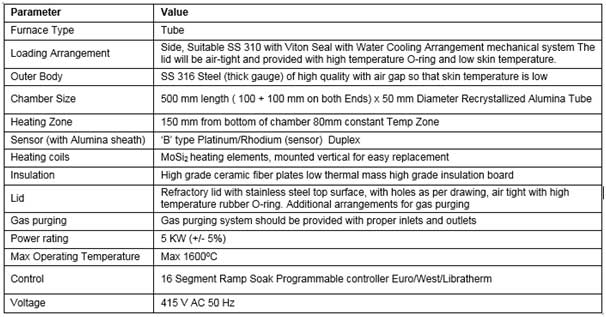

11) TUBE FURNACE

CALIBRATION CERTIFICATES

Furnace is air tight and provision for air purging

Electrical & detail drawing of the furnace will be provided

CONTROL PANEL

A separate control panel having the fallowing accessories

Digital Display Micro-Processor PID Temperature Programmer – Eurothermmake Model 3216 or equivalent West Make

Phase angle control Thyristor Power Drive

Safety Controller

Air Break Magnetic Contactor / SSR

Miniature Circuit breaker for load

Ammeter & Voltammeter

Indicating LED lights, Rocker Switch etc.

Safety Fuses for over load

TC broken indication with auto trapping and inter lock

Heating and cooling rate option from 1 °C/Hr. to 300ºC/Hr.

12) 1700◦C FURNACE

HIGH TEMPERATURE MUFFLE FURNACE

MODEL NO -: SFE03012

MAXIMUM TEMPERATURE -: 1700 °C

USEFUL CHAMBER DIMENSIONS -: APP. 150X110X240 MM (WXHXD) CHAMBER VOLUME: APP. 3.9 LITERS,

TEMP. CONTROL -: MICROPROCESSOR BASED PID PROGRAMMABLE TEMPERATURE CONTROLLER,

CONTROLLING SENSOR -: B TYPE T/C,

TEMPERATURE UNIFORMITY -: +/ 5 DEG.C,

HEATING ELEMENT -: MOSiO2,

MAX. POWER -: APP. 4 KVA,

VOLTAGE -: 230 V 1 PHASE AC SUPPLY,

WEIGHT OF FURNACE WITH CONTROL UNIT -: APP. 70 KG.