LABORATORY OVEN – Bacteriological Incubator (Natural Convection)

- Construction -: Double walled construction.

- Insulation-: 3 Inch Thick PUF insulation ensures stable temperature & reduced energy Consumption.

- Observation Door-: Full view Acrylic door with gasket to view samples inside the chamber.

- Heating System-: Heating elements made from the best Quality Kanthal DSD wire are used on refractory supports.

- Safety-: Additional Safety cum stand by thermostat to cut off the Heater supply in case of overshoot of temperature.

- Supply -: 230 V AC, Single Phase , 50 Hz

- Temperature Range -: 5° C above ambient to 60°C

- Temperature Accuracy -: ± 0.5° C.

- Trays -: Specially designed Stainless steel Rod trays ensure uniform temperature distribution.

- Standard Model -: InsideS.304 mirror finish &Outer Mild steel (CRCA) sheet with powder coated.

- Control System-: Imported Microprocessor based auto tuned PID controller with CE mark & dual display of Set value & process value for precise control of temperature.

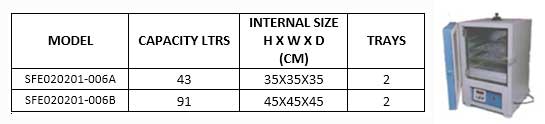

TECHNICAL SPECIFICATION

REQUIREMENT FOR INSTALLATION

- Place the chamber where ventilation is good.

- The chamber must be operated in an ambient of 22◦ C ~ 30◦ C.

- Leave minimum 300 mm. Space from the sides and leave 300 mm. Space from the backside.

- Place the chamber horizontally levelled.

- Give stabilized electric supply (230V ±5%, 50Hz, 1 Phase, 32 Amp). It is recommended to use a voltage stabilizer (KVA).

- Proper grounding of the chamber to get satisfactory operation of chamber.

- Do not test any product in the chamber, which is capable of generating combustible mixtures.