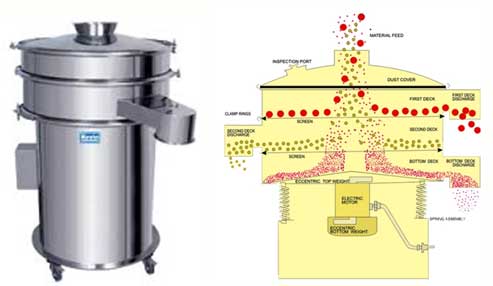

VIBRO SIFTER

Vibro Separators are circular unitary gyratory screens used to separate mass composition of solids from solids, and for gradation of materials as per particle size, having wide range applications.

Has been designed in order to achieve the multiple plane vibration by suitable assembly of the specially designed Vibratory motor (constructed for this purpose) having eccentric weight at the top and bottom ends of the motor shaft. The motor is mounted vertically at the centre of the screening assembly, on a circular base by means of springs which allow the Unit to vibrate freely. The springs absorb the vibrations and prevent them to be transmitted on the floor.

The top weight causes vibration in the horizontal plane which causes the material to move across the screen towards the Periphery. The lower weight acts to tilt the machine which causes vibration in the vertical tangential axis. The angle of lead of the lower weight with relation to the upper weight provides variable control of the screening pattern.

Thus the material moves across the screen and also in the vertical and tangential planes enabling maximum screening.

- arrangement can be provided

- Safe earthing system

- Faster output at low power consumption

- High Degree of surface finish

- All contact parts made of SS 316 as per GMP standard

- Easy dismantling and cleaning

KEYWORDS

- weight at the Centre of the base plate of screening

- Screening unit consists of SS 304 / 316 screens sandwiched between SS 304 / 316 hopper and bowl with help of special clamp with gasket. This in turn is clamped to the base plate

OPTIONS AVAILABLE

- ScreeningGMP unit with SS 304 machine body base instead of MS

- Dust cover or lid for hopper assembly

- SS 316 contact parts

- Castor wheels for mobile unit

OPERATION

The top weight on the motor shaft rotates in a plane close to the centre of the mass of assembly. Rotation of the top eccentric weights creates vibration in the horizontal plane which causes material to move across the screen cloth to periphery increasing the horizontal throw, causing oversize material to discharge at a faster rate.

The bottom eccentric weight rotates below the Centre of mass creating tilt on the screen giving vibration in vertical and tangential plane. Increasing the vertical component of motion, this promotes turnover of material on thescreen surface helping maximum quantity of undersize material to pass through the screen. Rugged Springs placed over the circular motor base amplifies the vibration

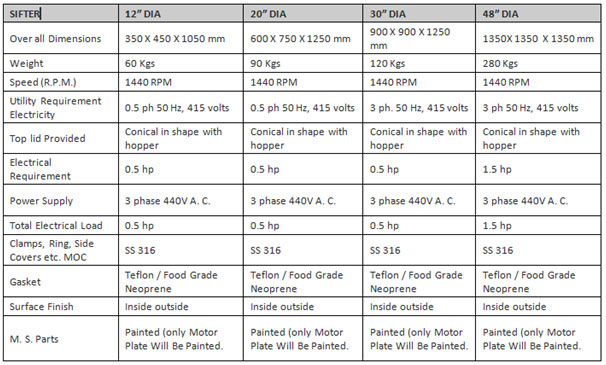

SPCIFICATIONS

Note -: Models for large scale, Small Scale, and Lab Size Vibro Sifter are also available

SALIENT FEATURES -:

•Available in various models providing screening diameter of 12″, 20″, 30″, 36″, 48″, 72″ etc.

•Portable and compact.

• Electric power requirement less than other machine of the kind in the industries & lower energy consumption compared to reciprocating vibratory system.

• Standard machine are with TEFC motor explosion proof / flame proof motor material.

• SS 316 quality contact parts.

• Special requirement like brushing arrangements, SS lid with charging port and spring loaded outlets.

• Wide range of screen sizes 4-300 Mesh.

• Double& Triple deck screens with outlet and hopper for bottom deck available on request