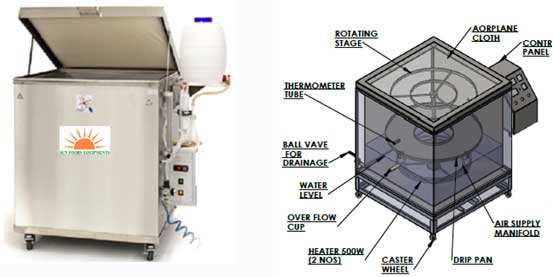

HUMIDITY CABINET (ASTM D1748-02)

APPLICATION

This test method is used for evaluating the rust-preventive properties of metal preservatives under condition of high humidity.

INSULATION

Rockwool

STANDARD MODEL

Inside S.S. 304 mirror finish & Outer Mild steel (CRCA) Sheet with powder coated.

GMP. MODEL

Inside SS 316 OR 304 mirror finish & Outer SS304 mirror finish.

CONSTRUCTION

•Double wall thermostatic cabinet

• Hinged cover consisting of two layers of desized cotton cloth mounted

On an SS frame

• Desized cotton cloth conformingto military specification MIL C-5646F

• Water level regulating system for automatic adjustment of the water level consisting

Of one 20 litres carboy, 2000 ml Erlenmeyer flask, glass and rubber tubing

• Low-level water device (203MM)

• Air supply and metering system:air filter, needle valve, rota meter, pressure gauge, pressure regulator

Filtering trap and tubing

• Tank equipped with draining tap

• Electric heating with 2 armoured stainless steel immersion heaters

•Air flow rate automatically monitored

• Humidity sensor

• Rotating stage at 0.33 rpm geared by and electric motor for the suspension of 33 steel test panels by means of the suspension hooks

• Circular drip pan mounted on the rotating stage

TECHNICAL SPECIFICATIONS

1) Cabinet Chamber Size = 740 X740x725 Mm (WDH)

2) Heating Load = 500w (1 No. Spare Heater)

3) Max. Temp. = 100 ̊C

4) Operating Temp. = 48.9 ̊C (Humidity Temp.)

5) Electric Supply = 220V Ac 50/60 Hz

6) Control Panel = Temp.Controller, Safety Controller, SSR, Temp Sensor,VFD for 3ph.Gear Motor, MCB Etc.