LABORATORY OVEN- Lab. Drying Oven – 400◦C (High Temperature)

- Construction -: Double walled construction.

- Insulation -: 4 Inch High grade glass wool insulation.

- Door -: Single door fitted on heavy cast & chromium plated brass hinges with spring and roller type latch.

- Air Draft -: Forced air draft is provided by means of Blower fitted at the bottom of the Oven (There is no re- circulation of air).

- Blower Motor -: 1/12 HP, TEFC, F-class insulation, Single Phase, 1440 RPM, 230 Volts.

- Heating System -: Heating elements made from the best Quality Kanthal DSD wire are used on refractorysupports.

- Supply -: 230 V AC, Single Phase , 50 Hz

- Temperature Range -: 50° C to 400°C

- Temperature Accuracy -: ± 2° C.

- Trays -: Adjustable Stainless steel Rod trays / G.I. wire mesh trays.

- Standard Model -: Inside S.S.304 mirror finish & Outer Mild steel (CRCA) sheet with powder coated.

OR Inside Mild steel (CRCA) with heat resistant aluminium paint & Outer Mild steel

(CRCA) sheet with powder coated. - Control system -: Imported Microprocessor based auto tuned PID controller with CE mark & dual display of Set value& process value for precise control of temperature.

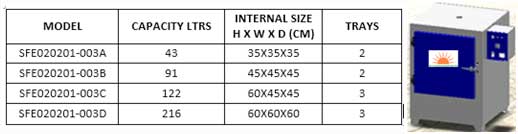

TECHNICAL SPECIFICATION

REQUIREMENT FOR INSTALLATION

- Place the chamber where ventilation is good.

- The chamber must be operated in an ambient of 22◦ C ~ 30◦ C.

- Leave minimum 50 mm. Space from the sides and leave 300 mm. Space from the backside.

- Place the chamber horizontally levelled.

- Give stabilized electric supply (230V ±5%, 50Hz, 1 Phase, 32 Amp). It is recommended to use a voltage stabilizer (KVA).

- Proper grounding of the chamber to get satisfactory operation of chamber.

- Do not test any product in the chamber, which is capable of generating combos.